I'm kind of an asshole, by natural tendency. I like to be right too much, and my brain will still instantly start debating anything anyone says to it. "The sky is blue." "Hrmm, I dunno, that looks like more of a Robin's egg than a pure spectrum blue." Over time I have gotten better at keeping these thoughts on the non-fucking annoying side of my mouth. Being into things like comics and outdoor gear and knives has actually done a lot to mitigate some of my worst tendencies, because when it comes to things like brands of ink, tent designs, and blade shapes, it's all about individual preference. It's very rare in my fields of interest that you can say "this is the best there is, and everything else is crap." Usually the closest you can come is saying that for a specific application, and given certain preferences, a certain thing would be the most likely favored. You certainly wouldn't want a wharncliffe style blade for a task better suited to a clip point, but which exact clip point you might want is as personal as your fingerprints. As I've matured, I've been able to take these principles from my own interests and apply them to things like music and film tastes (infamous sticking points for nerds where we lose all sense of humor about what we're talking about and become really repulsive), and it's made me, incrementally, a better person to be around.

I'm kind of an asshole, by natural tendency. I like to be right too much, and my brain will still instantly start debating anything anyone says to it. "The sky is blue." "Hrmm, I dunno, that looks like more of a Robin's egg than a pure spectrum blue." Over time I have gotten better at keeping these thoughts on the non-fucking annoying side of my mouth. Being into things like comics and outdoor gear and knives has actually done a lot to mitigate some of my worst tendencies, because when it comes to things like brands of ink, tent designs, and blade shapes, it's all about individual preference. It's very rare in my fields of interest that you can say "this is the best there is, and everything else is crap." Usually the closest you can come is saying that for a specific application, and given certain preferences, a certain thing would be the most likely favored. You certainly wouldn't want a wharncliffe style blade for a task better suited to a clip point, but which exact clip point you might want is as personal as your fingerprints. As I've matured, I've been able to take these principles from my own interests and apply them to things like music and film tastes (infamous sticking points for nerds where we lose all sense of humor about what we're talking about and become really repulsive), and it's made me, incrementally, a better person to be around.Certainty usually only comes when something is clearly inferior for anyone's uses- pink erasers, leaky tents and knives whose locking mechanisms break and close on your fingers, say. It's rare that you can ever say "this is the best of this thing, everything else is inferior, tastes and preference be damned."

Well, the asshole in me is filled with glee to be able to tell you all that this cutter is the best you can buy- better than any other brand, better than any other design by the same company, with absolutely no contest. Thanks to a friend of mine I was able to obtain one at half price, and it arrived today. Here it is, new in it's package:

Here's a closeup of the label:

It's made by the Japanese, who have evidently taken their level of craft making Samurai swords and applied it to making box cutters.

It's made by the Japanese, who have evidently taken their level of craft making Samurai swords and applied it to making box cutters.My pure joy with this thing starts at the box. The instructions are clear and the graphics are not only clear, but well laid-out and very attractively designed:

And like all Japanese packaging I've ever encountered, it's a jealousy-inducing combination of incredibly tough and easy to open. The plastic bubble holding this thing in is one of the most solid plastics I've ever encountered in this role, but they don't glue it to the cardboard, making it impossible to open. Instead, they have one staple at the bottom, and once you break that you simply slide the totally intact information card (which is important because it's so useful and informative) up and out of the plastic. You could slide it down and re-staple it and it could be as solid as when you bought it.

And like all Japanese packaging I've ever encountered, it's a jealousy-inducing combination of incredibly tough and easy to open. The plastic bubble holding this thing in is one of the most solid plastics I've ever encountered in this role, but they don't glue it to the cardboard, making it impossible to open. Instead, they have one staple at the bottom, and once you break that you simply slide the totally intact information card (which is important because it's so useful and informative) up and out of the plastic. You could slide it down and re-staple it and it could be as solid as when you bought it.

Here it is out of the box. The central shaft is heavy gauge stainless steel. The grey painted metal surrounding it and making up the handle? CAST ALUMINUM. Except for the two heavy-duty red plastic parts you see this whole thing is made of solid metal. The clever ribbing helps you maintain a comfortable grip AND keeps it feeling light despite the tough construction.

From above you an see how thick and hand-filling that handle is. From here you can also see one of the knife's best features, which is the forward-mounted locking screw.

From above you an see how thick and hand-filling that handle is. From here you can also see one of the knife's best features, which is the forward-mounted locking screw. What's the big deal with that? Well, first of all, having a locking screw at all is very important if you're going to use the blade for cutting anything that may bind around the blade and pull it backwards of forwards, like very heavy cardboard, thick foam core, matte board, wood, etc. Pretty much everyone puts the locking screw here on the side:

What's the big deal with that? Well, first of all, having a locking screw at all is very important if you're going to use the blade for cutting anything that may bind around the blade and pull it backwards of forwards, like very heavy cardboard, thick foam core, matte board, wood, etc. Pretty much everyone puts the locking screw here on the side:

Oh, great, so the mechanism responsible for holding my blade steady so I don't slip and find out what my finger bones look like is right where I'm holding the fucking knife, so I'll be sure to rub back and forth on it while I make aggressive cuts. What a great way to ensure that it has a greater chance of failing at the times my risk of serious injury is highest!

On top of that, this makes the knife a two-handed knife, because you can't really lock the blade with the same hand you're holding it with, at least not without awkwardly and dangerously shifting your grip.

Now look at the NT cutter when you're holding it:

That locking screw is RIGHT IN FRONT of where your thumb will naturally rest when cutting. All you have to do is reach half an inch forward and you can lock or unlock your blade TIGHTLY. When that screw is tightened that blade may as well be welded in. The screw has great, sharp metal texturing so you can get really good purchase on it and tighten that screw with little effort and no slipping. AND they even had the foresight to engrave (!) an arrow turning in the direction it locks, with the word lock in the center.

That locking screw is RIGHT IN FRONT of where your thumb will naturally rest when cutting. All you have to do is reach half an inch forward and you can lock or unlock your blade TIGHTLY. When that screw is tightened that blade may as well be welded in. The screw has great, sharp metal texturing so you can get really good purchase on it and tighten that screw with little effort and no slipping. AND they even had the foresight to engrave (!) an arrow turning in the direction it locks, with the word lock in the center.In this photo from the front you can see that the cast aluminum runs not only outside but inside the knife as well. This thing is basically a piece of metal- you'd need the Mythbusters to damage it in any way.

The blades are snap-off, but they're probably NOT what you're used to in snap off blades. The Osaka-based company that makes the cutter whose side-mounted locking wheel I just trashed, makes great blades, as does every Japanese utility blade manufacturer I'm aware of. As far as I can tell they're all based in Osaka, too. From my knife interests I know that Japanese steel is of especially high quality and sought out around the world, but only recently did I become aware that even in the world of snap off knives for utility blades, the different companies are in a pitched arms race, all producing roughly identical blades of incredible quality, all of which seem like Elf steel when compared to the crap X-acto uses. You almost jump in the air when you cut something with one of these for the first time.

I used to think a new X-acto blade was the sharpest anything could get, until I learned how to sharpen my own knives. Nowdays my pocket knife is sharper than a new X-acto blade. The Japanese blades are sharper than anything I could possibly produce by hand. You have to push and X-acto blade to make it cut. These Japanese blades are like a gopher straining on a leash- you merely touch the surface of something- paper, cardboard, anything- and they seem to want to burrow in, as if they were pulling themselves forward.

Now, you're thinking, great, they're sharp, but aren't snap off blades weak?

Usually, yes. But with these Japanese snap-offs aren't designed to be broken by hand. You need pliers, or the conveniently included blade snapper:

Usually, yes. But with these Japanese snap-offs aren't designed to be broken by hand. You need pliers, or the conveniently included blade snapper: I broke one off once accidentally, while batoning wood, which means I push-cut and then twisted the blade hard. Aside from that, these aren't going to break until you decide to break them. And then they break cleanly- I've used snap-off blades that left ragged edges before.

I broke one off once accidentally, while batoning wood, which means I push-cut and then twisted the blade hard. Aside from that, these aren't going to break until you decide to break them. And then they break cleanly- I've used snap-off blades that left ragged edges before.The blade changing system is extremely easy to use. You push the red button one way and then you pull the blade magazine out. The blades are held securely in place and won't spill out at you. You can load 6 blades at once. The knife comes pre-loaded with 2 blades.

As good as they are, I don't even recommend these blades, because they make something even BETTER:

As good as they are, I don't even recommend these blades, because they make something even BETTER: Here's a description of what you're looking at: "UltraMax® ultra-sharp premium heavy-duty snap-off black blades, exclusively designed for maximum cutting performance, are ideal for applications where superior sharpness is required. These blades made from high quality carbon tool steel are developed using a special double honing process for extreme sharpness and are 25% sharper than our Heavy-Duty LB blades. "

Here's a description of what you're looking at: "UltraMax® ultra-sharp premium heavy-duty snap-off black blades, exclusively designed for maximum cutting performance, are ideal for applications where superior sharpness is required. These blades made from high quality carbon tool steel are developed using a special double honing process for extreme sharpness and are 25% sharper than our Heavy-Duty LB blades. "I have used these before and I can vouch for these being almost science-fiction sharp. These blades do not just adequately cut things like PVC pipe, leather, heavy rubber, and hard wood- they seem to want to burrow through to the other side of these materials on contact. And their edge lasts really, really long. Once you stuff these blades into an NT cutter (I recommend these instead of NT's blades because they're significantly easier to find in the U.S. and basically identical) you basically have a short lightsaber in your hand.

While photographing for this review I had the idea to compare the NT cutter to an X-acto knife, thinking that I'd demonstrate that no tool is totally perfect, and that the NT's durability and versatility in being able to cut everything from drywall to paper meant some sacrifice in dexterity. What I ended up proving was that X-acto blades suck a lot worse than I ever imagined.

I started off with a task I was sure the NT wouldn't perform nearly as well as the X-acto, tight, curved cutting. I drew some tight, hard-to-follow curves, like this:

And then I followed them with both blades. I noticed that precision-gripping the NT was actually very easy, much moreso than I'd have thought:

And the results surprised me.

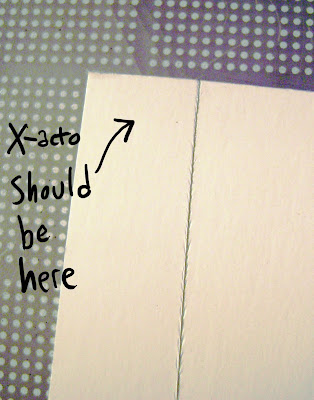

And the results surprised me.The X-acto did take the tight curves slightly more smoothly. In a super-tight turn the NT cutter will bend the paper slightly, unless you pick up the blade partway through. (I did these cuts without picking up the blade.) However, the NT praxtically burrowed through my paper into the self-healing board below, and with no pressure it cut all the way through. My X-acto cuts, while very slightly smoother, did not make it through everywhere, and I'd have had to make about five small additional re-cuts to free the flap, as you can see below:

Then I decided to try my most common X-acto task, cutting a bunch of pages flush.

It took me 20 cuts to make it through these pages, and even using a metal ruler as a guide the X-acto's tendency to divert and flex left a very slight curve in the cut. (I'll grant that I wasn't using my best cutting technique, though . I'll post a tutorial on cutting technique next week. )

Whenever I use an X-acto hard like this, my hand always hurts in these places:

Whenever I use an X-acto hard like this, my hand always hurts in these places:

Not only did the NT cutter do the job in 11 cuts instead of 20, it's cuts were cleaner, and the NT is so comfortable to hold I didn't feel like I'd cut through a thick stack of paper at all. And the NT edge was straight.

Next I moved to thin foam core. The X-acto (brand new blade) pushed into and bent the foam core card board fa r more than the sharper NT:

And for all that damage, it didn't even cut all the way through on the first pass. (The NT cut is a bit ragged because I did it too hard and too quickly- again, video on good cutting next week. )

My next material was the plastic bubble the knife came in. I made two attempts but could not make the X-acto fully penetrate the plastic, let alone cut forward. I actually pushed harder than was safe- if it had slipped I could have been badly injured. The NT cutter shot through the plastic like a tuna through water.

If you look at the blades in profile, the NT and the X-acto have the same steel thickness, it's just that the X-acto are an inferior steel. (I should note at this point that I'm using special X-life heavy duty X-acto blades, not just regular X-acto blades. Even their "premium" steel sucks.) I break the tip off my X-acto blades within the first five cuts, no matter how lightly I'm cutting. Like I said before, I've only broken a Japanese snap-off blade batoning in wood, which is really something I should have been doing with a chisel.

As a neat little bonus I thought I'd try the same tests with my trusty pocket knife:

As a neat little bonus I thought I'd try the same tests with my trusty pocket knife: I maintain a good edge on all my blades, and my pocket knife in particular, since it's main uses are cutting paper, and doing occasional minor surgery on myself or others, such as removing a splinter or callus. On a good day I can do better than the Razor blades you'd buy in a drug store. (Although the Japanese make shaving razors that I couldn't hope to match.)

I maintain a good edge on all my blades, and my pocket knife in particular, since it's main uses are cutting paper, and doing occasional minor surgery on myself or others, such as removing a splinter or callus. On a good day I can do better than the Razor blades you'd buy in a drug store. (Although the Japanese make shaving razors that I couldn't hope to match.)My knife went through the foam core as well as the NT, just with a little more resistance due to the MUCH thicker blade.

Same deal with the plastic, puncturing it was a little harder with my thicker knife, but once it was in it sailed right through the hard plastic.

Same deal with the plastic, puncturing it was a little harder with my thicker knife, but once it was in it sailed right through the hard plastic. Having a good cutter with replaceable blades in indispensable to the artist. Cartoonists are always cutting tough, fiberous materials such as stacks of paper, thick watercolor sheets, minicomics, cardboard boxes, matte board, foam core, and so on. I've had my hand crippled for a full day after trimming minicomics by hand, and that would not have happened if I'd had this tool.

Having a good cutter with replaceable blades in indispensable to the artist. Cartoonists are always cutting tough, fiberous materials such as stacks of paper, thick watercolor sheets, minicomics, cardboard boxes, matte board, foam core, and so on. I've had my hand crippled for a full day after trimming minicomics by hand, and that would not have happened if I'd had this tool.The NT cutter cannot be bought online- at least not by a regular person. But stores can order them. (Edit: Comic Tools Reader Sam found a place! http://www.carpediemstore.com/listCategoriesAndProducts.asp?idCategory=2228 )This is it's entry on the NT website: http://www.ntcutter.co.jp/L-2000RA.htm

It's not a cheap tool, running in the 30 dollar range- but there's nothing quite like it, and this thing is built like a horse shoe. You'll be figuring out which kid to give it to on your death bed. Alhough there are some tasks which an X-acto would be better suited to (By the way, Olfa, the company that makes the high-strenth blades I reccomend for the NT cutter, makes X-acto style blades in much better steel.), the fact that the NT cutter performs those same tasks adequately, while performing many tasks better, and several tasks that the X-acto cannot perform at all, means that the NT barely represents any compromise of function in favor of versatility. If you only have one cutting tool, this should be it.

Next week, proper cutting technique.